The human desire to create and replicate three-dimensional objects is nothing unusual. Mankind has been doing it for thousands of years using an array of materials.

Far more recently came the introduction of computers, which has revolutionized every aspect of life as we know it. Computers paved the way for dozens of new technologies and in the late 1960s the first 3D scanning technology was developed. Things have moved on considerably, and now the ever-emerging world of 3D technology continues to disrupt a range of industries.

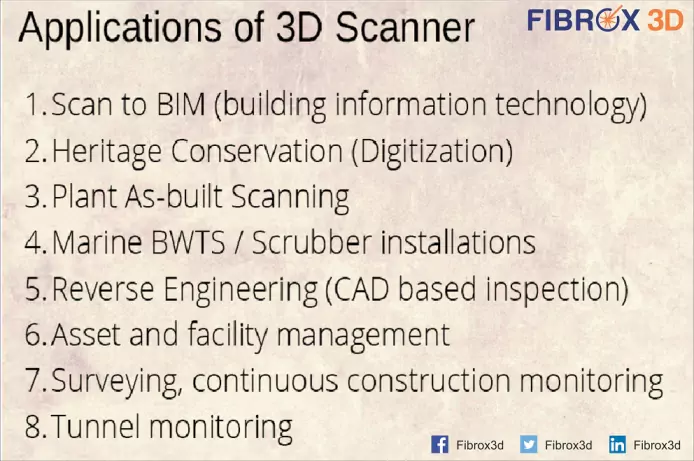

3D Scanners have continued to considerably improve upon their technology whilst becoming more affordable, smaller, and much easier to use. Today, we are going to look at some of the real-world applications of 3D scanning.

Education

3D scanning is starting to become prevalent in classrooms all around the world. By using sculpting clay or a similar medium, students with very limited 3D CAD modeling skills are able to create and 3D print completely unique models that would be near impossible to produce using software only.

We are huge advocates of 3D scanning in the classroom and recently started work on a lesson plan that involves students’ designing, scanning, and printing their very own ergonomic pen. Going forward we will be creating a number of lesson plans that combine the use of 3D scanning and 3D printing.

At Fibrox3D, a key focus is on 3D technology in education and we often consult our global network. Many teachers agree that 3D Scanning sits perfectly alongside 3D printing in teaching key curriculum principles and allowing for unique 3D model creation.

Architecture

The ability to scan and analyze buildings in high detail makes 3D scanning a hugely attractive proposition when conducting architectural surveys. 3D scanning provides the user with extremely accurate measurements with high precision and the ability to fully utilize, visualize, and modify data with CAD.

The ability to rapidly capture high accuracy information means widely utilizing productivity and time, which is most important when delivering results to the end customer.

As well as for surveying purposes, 3D scanning is a perfect solution when looking to reverse engineer, whether that be for a building exterior or even some internal furniture.

We got a recent requirement for detailed scans of some exterior details that had degraded. Mainly these types of requirements come from conservation architects. The objective was to conserve and replace cladding using modern materials, whilst replicating the look and aging profile that previously existed.

Art/History

3D Scanning is increasingly being used amongst artists and art historians. The scanning of artifacts to create reproducible 3D printed versions or for archiving and curating is one of the major uses within this industry. 3D scanning enables every form of cultural heritage to be classified, measured, analyzed and even shared amongst the researcher community.

Perfectly identical, richly detailed, true-to-scale copies of a piece of sculpture also represent an opportunity, not only to preserve but to teach and allow those interested to get hands-on without risking damage to a priceless item.

Perhaps an art historian is looking to restore an artifact that has degraded over time. 3D scanning is the perfect technique for assisting with effective restoration and conservation.

Medicine/Health

Throughout these years 3D technology has proven to be a crucial tool within health-related industries. Personally, a favorite application for 3D technology across all industries is that of prosthetics. 3D scanning enables the design and production of a prosthetic limb that is measured to remarkable accuracy, meaning maximum comfort, mobility and reduction in pain. Coupled with 3D printing, this process is a fraction of the time and cost of traditionally used methods.

Increasingly, 3D scanning is also being used by health professionals for a detailed study of body parts, for example prior to a surgical procedure. Thorough planning and preparation of the site give doctors and surgeons the opportunity for more informed decisions and improved rates of surgical success.

The regular method of creating artificial limbs without 3D scanning involves manual measurement of the anatomy before a plaster cast is made. After the cast is produced, it must then be sent over to a manufacturer and there are various cases where manual measurement has resulted in prosthetics that are not suited for the patient due to inaccuracies. It is very important that a prosthetic limb is comfortable for the patient and 3D scanning can ensure this for every patient.

With 3D scanning, the whole process is much quicker, but more importantly, much more accurate. Within just a few minutes a 3D scan can be created that can be sent to a manufacturer digitally, reducing time and transport risks. If you look at the 3D scans below of the hand and foot, this adds a new dimension into prosthetics because it allows manufacturers to use the data to mirror and recreate parts of the body.

We are excited about the future of 3D scanning in prosthetics and we believe that when combined with 3D printing, there will be a revolution in the medical industry.

Engineering and Design

Huge potential for 3D scanning is an engineering and product design. The ability to scan any object and then use CAD for modification makes both reverse engineering and rapid prototyping an extremely streamlined process. Detailed measurements can be performed and investigation into mechanical properties is simplified.

In a similar respect to engineering, rapid prototyping and reverse engineering are fundamental to the design of most products. When working with a demanding clientele, any techniques that assist in better results and a faster turnaround are often welcomed. The introduction of 3D scanning certainly provides this.

As we continue to design and develop more effective materials for a range of purposes, we commonly look to mimic natural materials for their superior properties, be it plant structures or even fossils. What better way to study these complex arrangements and create a new design than through scanning and studying in high resolution.

Scientific Research

3D scanning permits the detailed study of any object. At any one time, research fellows around the world are studying an infinite array of materials. From advanced topography to optical measurements and archiving, the introduction of 3D scanning opens up a lot of possibilities.

Researchers have also begun to detect the degradation of mummy in Egypt over the years with the use of 3D scanning technology and capture all the requisite textures for the desirable greater good. And also building their very own scaled replicas to experiment with the object in detail.

The objective is to see how their material interacted with modern material to create a bridge between old aged technology to preserve something for years and respond to environmental stresses.

Full-Body Scanning

With 3D technology comes the endless possibilities of customization. Since no two human bodies are the exact same, what better subject to use when creating a unique 3D model. There are numerous services opening up around the world that enable the user to be 3D scanned and take home their very own 3D printed replica model of themselves.

Aesthetic body analysis, avatar creation, and custom-fitted clothing are just a few more of the applications concerning full-body 3D scanning.

Virtual Reality/Animation

The gaming industry is currently experiencing rapid advancement and 3D scanning appears to be playing a key role in this growth. The scanning of both people and environments is being performed to provide realistic simulation through gamification.

The recent advent of affordable virtual reality headsets is also proving to be a driving force in recent advancement and the increased use of 3D scanning. Major game developers have been creating gaming characters with 3D scanning for some time, however, as ease-of-use and affordability improve, more small-medium game and app developers can use 3D scanning to give gamers a better user experience.

Common Applications for 3D Scanning Software

Quality control

One of the most common 3d scanning applications for scanners and software is quality control.

In today’s highly competitive markets where each company is striving to produce the most accurate parts in the fastest amount of time, quality control is of the utmost importance. High-quality manufacturing processes can distinguish a business from its competitors, and this makes precise, accurate, and repeatable quality control processes a vital part of any manufacturing plant. 3D scanning software can help firms improve the quality and speed of their inspections by creating detailed 3D models of manufactured parts and offering workflows optimized for specific industries. Each part can be scanned and the digital model can be evaluated to make sure every area on the part is within the specified tolerances.

Inspection software (i.e. GOM) enables users to inspect CAD (computer-aided design) files, 2D drawings, and multiple parts. Additionally, the inspection software offers CMM (coordinate measuring machine) style reports and color maps that enable quality engineers to immediately identify parts that are outside of specified tolerances.

Prototyping & 3D printing

Prototyping and 3D printing is another frequent use case for 3D scanning software. 3D scanners enable you to take a physical product, scan it into a digital format (e.g. the STL file format), and work with the digitized model to create prototypes that are then printed by 3D printers. The high level of precision enabled by quality 3D scanners significantly streamline this process because increasing the granularity of scan data greatly reduces the manual time required to create a solid model.

Reverse engineering & CAD creation

A very common challenge in the world of engineering and product design is reverse-engineering a physical product for which you do not have a CAD file. Using a 3D scanner that will capture the complex geometric characteristics of a given part is a great way to develop a CAD file when one is not available. Creating or sourcing high-quality CAD files early on in the reverse engineering process can greatly improve the results of the project by minimizing wasted time and guesswork based on inaccurate data. 3D laser scanner’s easy workflow has minimized CAD creation time and led to more successful reverse engineering projects.

CFD/FEA

CFD (Computational Fluid Dynamics) simulation is commonly used for flight and wind tunnel testing. FEA (Finite Element Analysis) is often leveraged to predict how a given part or product will react when exposed to forces like heat, fluid, vibration, etc. As these simulations and analyses are used to simulate conditions for industries like aerospace where safety is of the utmost importance, precise digital models are a must, and this is where 3D scanners and the associated scanning software comes in. The more accurate the 3D models, the more reliable the simulations.

One example of a company using 3D scanning software for CFD is the case of the North American Eagle project which challenged the 763 mph world land speed record.

Know more:

- 3D Scanning Technologies and Types