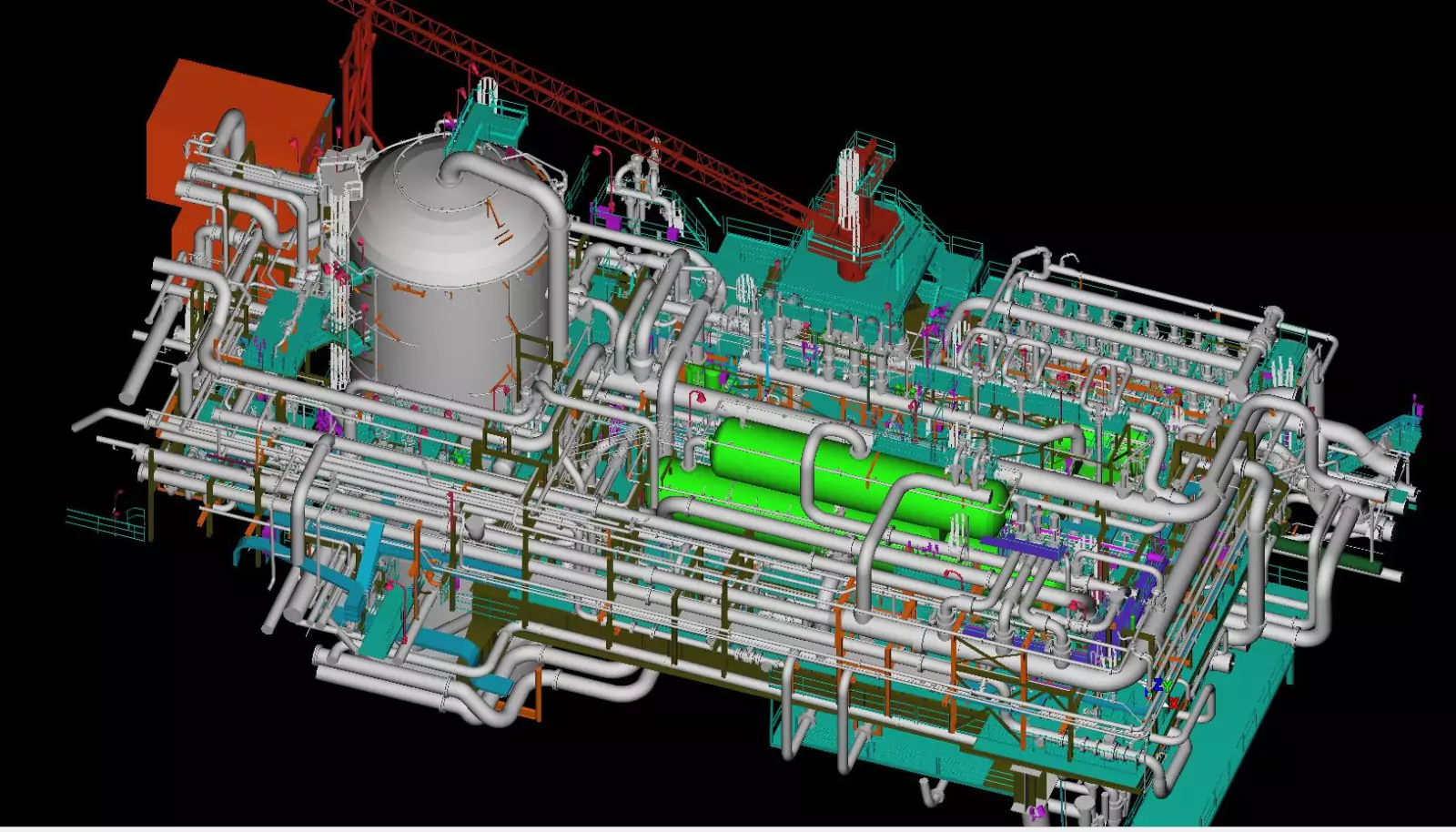

Plant As-built modelling

- Home

- Plant As-built modelling

Plant Design is aided by 3D modelling services. To increase engineering efficiency, cut expenses, and shorten design time, Plant 3D modelling services have become popular nowadays.

Learn about the quality, sustainability, time, and cost of the piping and instrumentation diagram:

A top-notch 3D model of piping and equipment Diagram

- Designing using intelligent things is simpler.

- Regardless of how frequently the plant design is altered, 3D-based plant models provide improved visibility, allow for zero mistakes and omissions, and save time and money.

- For the engineers, 3D-based plant models imitate real-world performance, look, and cost.

- Using 3D models, provide sustainability and aid in maintaining, monitoring, and optimising performance.

3D Model saves Time and money

- Engineers may realistically minimise design expenses and conflicts for higher efficiency and better-optimized design even before the facility is actually built. By including customers in the design process from the outset, Fibrox3D, a 3D modelling service of plant design engineering, provides clients with efficient and effective solutions and helps them to make wise strategic decisions.

Advantages of 3D Modelling service on Plant Design:

- Visualisation gives the capacity to see potential outcomes and alter them as necessary during the design process.

- Good appearance and presentation by producing model renderings and animations, 3D services make it simple to construct proposals or evaluations.

- Assessment allows you to browse the 3D plant model and examine any modifications.

- Enhanced efficiency to verify and check plant models in 3-dimensional model are more productive and enable faster design output than 2D.

- Broadened focus of 3D plant designs that are created by a service may readily include the most recent design revisions, expanding the possibilities for engineering.

- Reliability of 3D intelligent plant models enable the testing of various scenarios, provide quality control, guard against mistakes, and verify designs to cut costs.

- Elimination of Physical Models: 3D services eliminate the demand, expense, and time for physical prototype models.

- Payment: Automatic bills of materials are generated using 3D service-based planet models for easier procurement.

- Better Data Management: 3D service-based plant models provide effective data management, organisation, and design.

- Standardised drawing and 3D plant modelling techniques.

- Automation will improve rendering speed and accuracy, which will increase client satisfaction.

- Forecasting Material Consumption: By precisely forecasting material consumption, 3D plant modelling may cut down on the need for building materials and fabrication time.

- Uphold Standards: The Piping 3D Model is compatible with all international standards.

- Smart Data Report Management provides proper accounting of materials as utilised in data reporting.

- Instrumentation and intelligent piping Diagrams can be created in accordance with processes.

- diminishing of human resources To ensure the most efficient use of resources, 3D-based plant modelling significantly decreases the workforce.